Products

Customer-driven product design backed by our commitment to on-time delivery, performance consistency, and fast technical and logistics support.

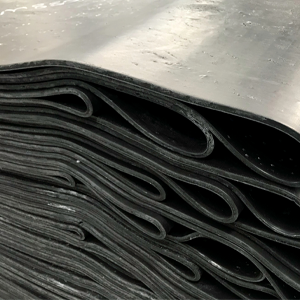

McLube offers mold release agents, industrial lubricants, anti-stick coatings, and other process aids to the manufacturing, automotive, aerospace, energy, and defense industries. We also offer custom formulations tailored to unique processes and needs. Founded in 1954, McLube is family-owned and operated and headquartered in Aston, PA, USA. Our products are available globally through our divisions and distribution channel partners. Select a product category below to learn more: