Release Agents

Achieve process goals and secure your supply chain – Our release agents and custom formulations improve molding efficiency and are backed by our commitment to on-time delivery, consistent performance, and fast technical and logistics support

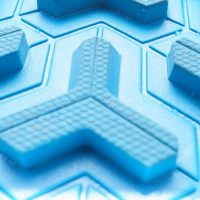

Molders and manufacturers around the world rely on our carefully tailored mold release formulas to provide consistent results for every cycle. Each McLube® release agent has been carefully formulated to provide unparalleled release characteristics for a specific material, process, or application. Whether your goal is to reduce costs, improve parts, or reach a sustainability goal, our experienced team of Formulation Chemists and Technical Representatives can help. We have spent decades on production floors around the world helping customers achieve their process-specific goals and solve their most complex manufacturing challenges. Our diverse line of release agents includes water-based, solvent-based, and 100% solution formulations for all natural and synthetic rubbers, plastics, urethanes, and composite materials. If we do not have an existing product that is perfectly suited to your application, then our team of Technical Representatives and Formulation Chemists will develop a custom mold release agent catered to your unique application. From delicate medical parts to some of the largest tires in the world, engine components to steering wheels, our team has the industry-specific knowledge and expertise required to optimize your process and achieve your process-specific goals.

Select your material or application

Need Help?

Release Agents by Type

Release Agents by Diluent